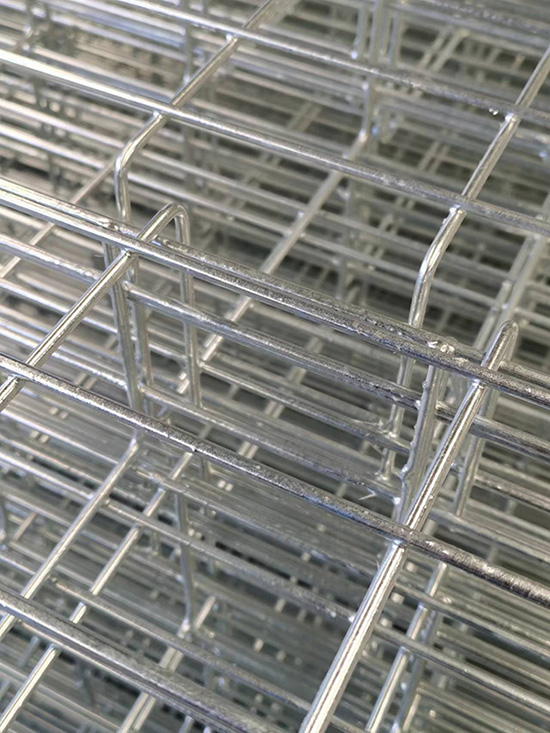

Previously the HDG wire mesh cable tray surface is somewhat rough with zinc dross. The below picture was the surface of our HDG basket cable tray before technology upgrade.

This is the surface apperance of raw HDG wire mesh cable trays after hot dip galvanizing. You can see there are lots of zinc burrs after zinc bathing. Normally we would rub off the zinc burrs off the cable basket trays, to get rid of sharp spikes hurting cables. It cost a lot of manual works. Thus the delivery time will be longer, and the cost will be high. What's more, some raised zinc covered on cable trays will be rubbed off. This would increase product defective rate.

After rubbing off the zinc burrs by our workers, the cable tray surface is getting not that rough. But it is still not so smooth. Check the picture above.

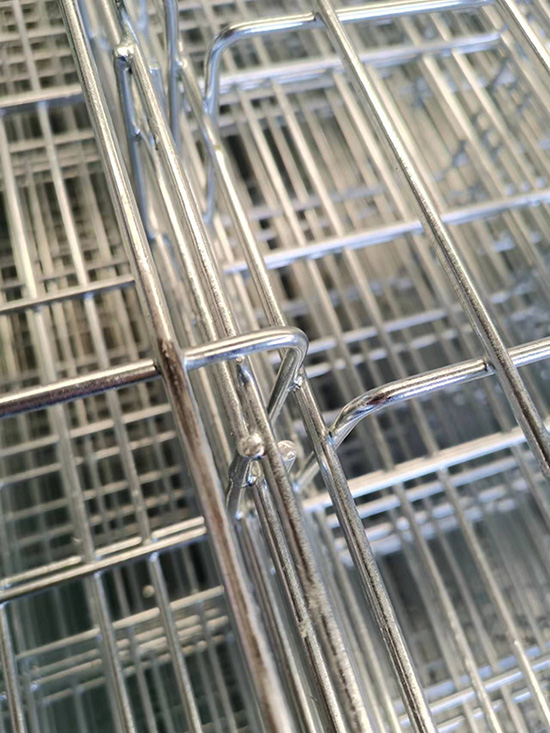

Now we have upgraded our hot dip galvanizing process technology, the HDG wire cable tray surface is improved a lot. Here is the photo:

The upgrated hot-dip galvanizing technology greatly improved our HDG wire mesh cable tray surface apperance. Meanwhile it help us cut manufacture costs, and shorten the HDG basket cable tray delivery time.

The new HDG wire mesh cable trays are not only smooth, but also much brighter in appearance. Our products are more competitive for solar energy projects. Welcome to request for short samples of our upgrated HDG wire mesh / basket cable trays.

Publish Date: 2024-02-29