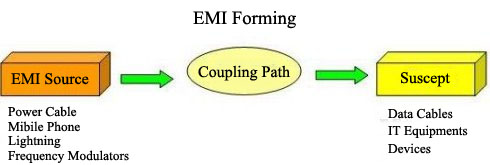

EMC (Electro Magnetic Compatibility) = EMI (Electromagnetic Interference) + EMS (Electromagnetic Susceptibility).

EMC is very important for EMI-sensitive devices to avoid performance degradation, function loss and damage. Using metalic cable trays can reduce the effects of coupling and improve EMC performance of devices. Wire mesh cable trays have EMC perormance as good as perforated channel cable trays. To use a cover it will get better. The EMC perormance of our wire mesh cable trays with covers are as good as fully enclosed cable trays.

EMC is very important for EMI-sensitive devices to avoid performance degradation, function loss and damage. Using metalic cable trays can reduce the effects of coupling and improve EMC performance of devices. Wire mesh cable trays have EMC perormance as good as perforated channel cable trays. To use a cover it will get better. The EMC perormance of our wire mesh cable trays with covers are as good as fully enclosed cable trays.

Following criterias below can help cable trays obtain good EMC.

- Make sure electrical continuity (view our technical guide for electrical continuity) is reserved, and connect cable trays to the earthing network every 15-20 meters.

- To use two separate cable trays for power and data cables. Never put power cables and data cables in the same closed compartment.

- To use a divider in cable trays if the required distance① cannot be met.

- Make sure different cable types cross at right angles (90 degrees).

- Make sure different cable types cross at right angles.

①Required distance between data cables and power cables as below:

| Installation Status with Data Cables | Minimum Distance (mm) | |

|---|---|---|

| 380V Power Cable < 2kV•A | Parallel laying | 130 |

| Either one is earthed | 70 | |

| Both are earthed and parallel length is ≤ 10m | 10 | |

| 380V Power Cable 2~5 kV•A | Parallel laying | 300 |

| Either one is earthed | 150 | |

| Both are earthed | 80 | |

| 380V Power Cable > 5kV•A | Parallel laying | 600 |

| Either one is earthed | 300 | |

| Both are earthed | 150 |

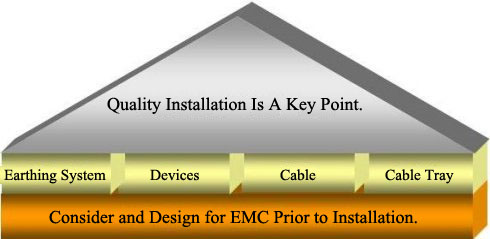

In conclusion, good EMC rely on EMC project design, equipments and installation quality. And among this, good quality of installation is a key point.

In conclusion, good EMC rely on EMC project design, equipments and installation quality. And among this, good quality of installation is a key point.