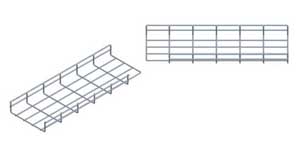

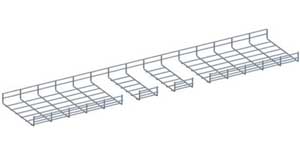

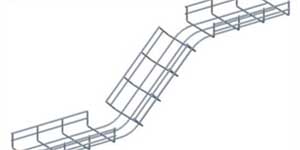

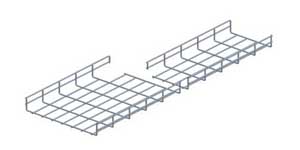

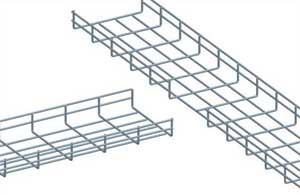

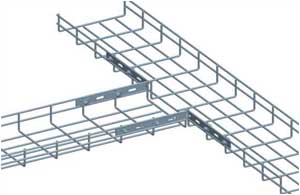

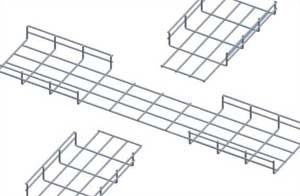

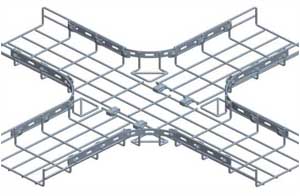

The bends, tees, crosses, risers and reducers of wire mesh cable tray can be easily and quickly made live at the project by using a bolt cutter. Since the jaws of the bolt cutter drags a layer of zinc across the cut end and forms a protective layer. When a wire cable tray is cut, the fact that a wire has been cut does not affect the level of protection. Let alone we have rubber caps to protect the cut ends.

The assembly guide below will help the cable tray installer make the bends and others without difficulty even he had never installed wire mesh cable trays before.

| Width / Type | Cut | Forming |

|---|---|---|

| 50mm Bend |

|

|

| 100mm & 150mm Bend |

|

|

| 200mm Bend |

|

|

| 300mm Bend |

|

|

| 400mm & 450mm Bend |

|

|

| 500mm Bend |

|

|

| 600mm Bend |

|

|

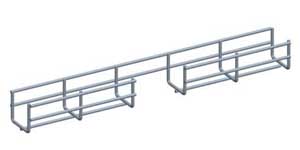

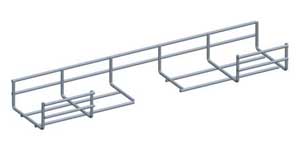

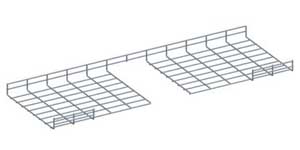

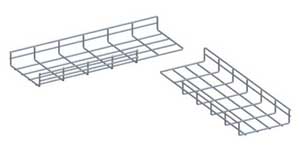

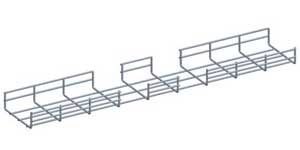

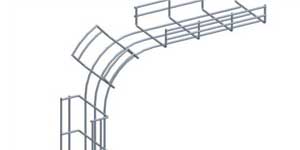

| 90° Bends Assembled From Two Straight Sections |

|

|

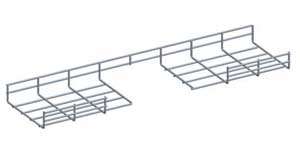

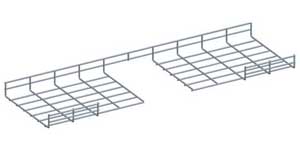

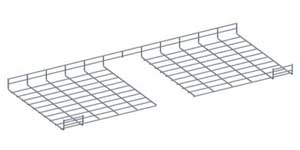

| Horizontal Angles |

|

|

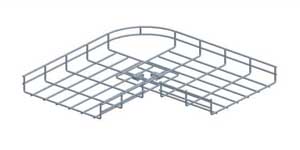

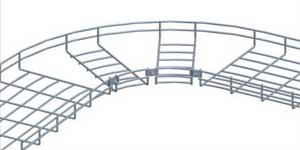

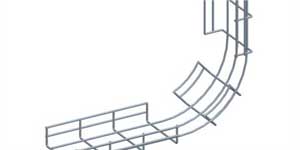

| 90° Large Radius Bends |

|

|

| Internal Risers |

|

|

| External Risers |

|

|

| Vertical Inside and Outside Bends |

|

|

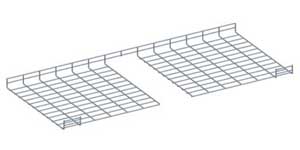

| Reducers |

|

|

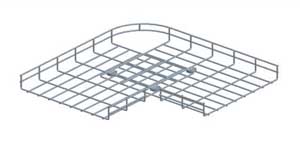

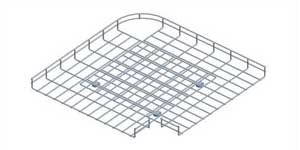

| Tees |

|

|

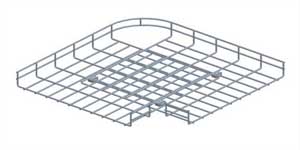

| Crosses |

|

|