Stainless steel wire basket cable trays are suitable for corrosive environments or food production industry. Usually SS304 cable baskets are ideal for the beverages industry, food and non-food. SS316L cable baskets are ideal for all harsh environments, especially recommend for marine environment.

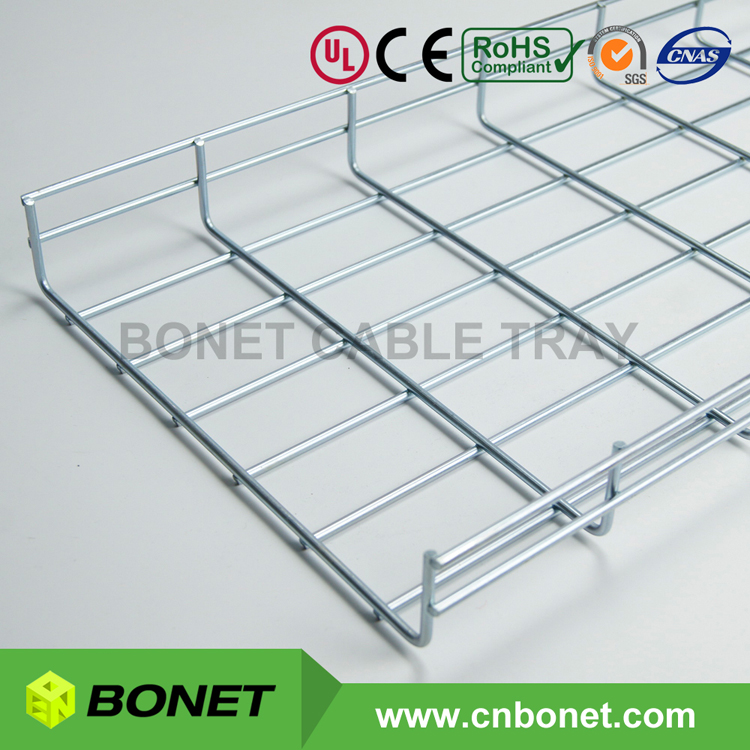

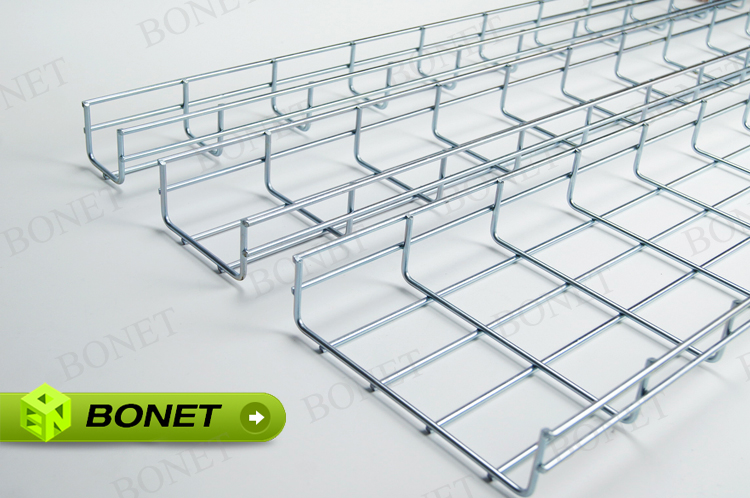

Bonet stainless steel basket cable tray sizes also start from 50mm wide to 600mm wide, available in 50mm, 100mm and 150mm standard depths, with bottom grid structure of 50mm x 100mm.

For stainless steel wire basket cable trays, only those welded by Medium Frequency Direct Current (MFDC) welding machines are reliable in welding strengths. AC welders are not qualified to weld stainless steel wires. The SS304 & SS316 basket cable trays manufactured by Bonet have smooth als[……]