I know many purchasing managers have rich experience of how to find basket cable tray suppliers. But before you have done order with them, how can you tell which supplier is good? Judging from webpages obviously is not enough.

Below are 6 tips from my 9 years’ experience in wire mesh cable tray business. I think they can be helpful for choosing a reliable basket cable tray supplier.

- Professional

Actually, many factories can produce wire mesh cable trays if you offer them drawing or sample. A company who can produce big mesh structure products may be able to produce basket cable trays. Frankly, I won’t suggest you to do so. After all, basket cable tray is an electrical product.

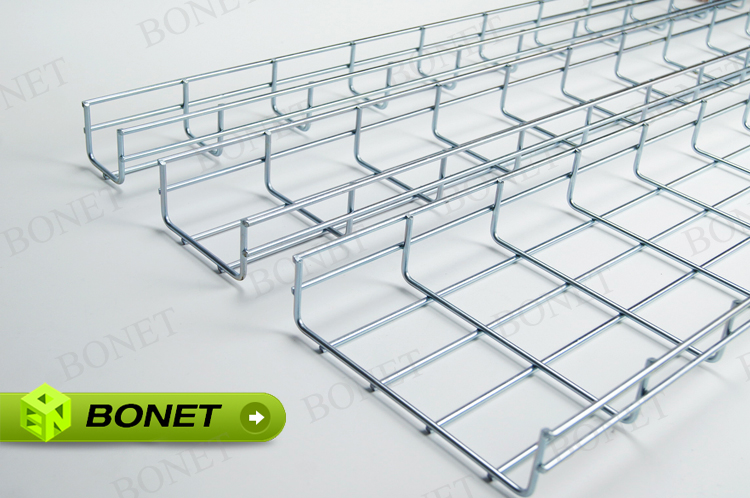

If you have been in cable tray business for several years, you will find that manufacturers make cable trays and cable ladders normally don’t make cable baskets, and vice versa. This is because the production line of these products is quite different, as well as supply chain. That’s why we see those professional cable basket manufacturers like Marco, Valdinox and my company Bonet only offer wire mesh cable trays.

There is a way to recognize whether the vendor is professional. If a company mainly sell basket cable trays, and they have various different accessories, that company can be called professional. You should know each accessory cost expensive mould fees. But take note a supplier displays many 3D product pictures do not mean they really have those items.

- Certificate

An experienced supplier normally will have various certificates. While don’t simply trust the certificates displayed on web pages. There are quite many fake certificates in China. Those certifications can be verified online are more reliable, such as UL. But I’m not telling a supplier with UL certificate can offer good basket cable trays. Making qualified samples and making mass production products are two different things.

In a word, suppliers have many certificates are just gaining more votes for themselves. But you still need to verify their quality by yourselves.

- Machines

The machines directly reflect the level of a manufacturer. Cable basket trays welded by Medium Frequency Direct Current (MFDC) welding machine are more reliable than those welded by AC welding machines. The welding quality of MFDC welder is better and more stable than AC welders. What’s more, only MFDC welding machines are qualified to weld stainless steel wires. If you don’t know what MFDC welding machine looks like, just check if the machine has an operating software to set welding data.

- Material

Material is important to affect cable basket quality from mechanical strength, welding strength to galvanizing quality. Make sure the supplier can meet four requirements below:

Firstly, no recycled steel and always content qualified stainless steel are used. Secondly, material yield (proof) strength meets min. 500MPa. Thirdly, raw material is drawn down to target wire gauge by at least two times. Fourthly, no minus wire gauge tolerance.

- Galvanizing

The quality of galvanizing directly affects the service life of basket cable trays. Normally we require zinc plating coating thickness meet minimum 12μm. Many suppliers are only able to make it 5μm to 8μm in mass productions.

Besides coating thickness, zinc adhesion is also important. If zinc coating thickness reach 12μm with good adhesion, the wire cable tray should pass at least 72 hours neutral salt spray test (NSS) without showing red rust.

A wire basket cable tray with good galvanizing should look bright and uniform on surface. But it is a misconception that the brighter the surface is, the better galvanizing it would be. In fact, the bright color has more relationship with zinc plating brightener. And if the surface is too shining, you should take care if NaCN is used during zinc electro galvanizing. Although NaCN is forbidden by government in many areas of China, it is till used for galvanizing in some workshops.

- Details

It’s a truth that product details can reflect the quality level. We can have a brief conclusion on supplier’s quality by following aspects:

- Accurate dimensions.

- Straight shaped in lengthwise direction.

- Bended in right angles.

- Clean and none scratch surface.

- No sharp wire cutting edges.

- Smooth imprint for both welding and bending.

Above are 6 tips from my career experience to help you choose a reliable basket cable tray supplier. Since equipment below wire mesh cable trays are all expensive especially in data center, the welding strength must be qualified and stable. And from my point of view, don’t let price be your primary reason to judge a supplier. You will feel sorry for your decision. Let’s take an example, you pay 1500USD to buy cable basket trays which finally rust within 3 years. And you pay 2500USD to buy cable basket trays which lasts more than 5 years. But the installing fee is the same. You can see which one is worthy.

Should you have any question or supplementary on choosing basket cable tray suppliers, please send email to danlic.dai@cnbonet.com.