In addition to simply routing and protecting cables a cable tray system must provide protection to life and property against faults caused by electrical disturbances, lightening, failures which are part of the system, and failures of equipment that is connected to the system. These protections can be obtained through proper bonding and grounding. Article 250 of the National Electric Code (NEC) provides the minimum requirements for grounding and bonding. Article 392 provides guidance and minimum requirements specific to cable trays.

To understand these Code requirements adequately, one should always be familiar with defined terms related to the subject matter. Understanding how the defined terms are used within the Code will provide users an improved understanding of how the rules apply[……]

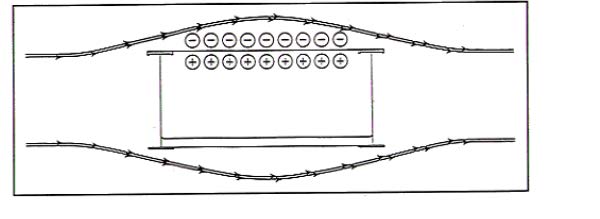

Best practice guide to cable ladder and cable tray systems (photo credit: elektro-ka.si)

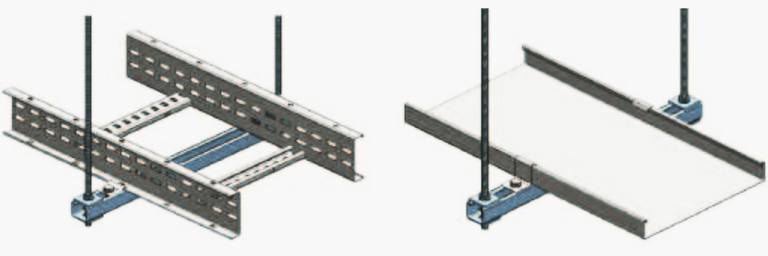

Best practice guide to cable ladder and cable tray systems (photo credit: elektro-ka.si) Channel type trapeze hangers – Installation with ladder and tray

Channel type trapeze hangers – Installation with ladder and tray