One of the most important choices when designing a cable tray system for corrosive or outdoor environments is the material. Steel cable tray with a Hot-Dip Galvanized after Fabrication (ASTM A123) finish has been used successfully for many years. Increasingly, however, aluminum is becoming the material of choice for cable tray systems. In these days of shrinking construction budgets, why would engineers, contractors, and end users choose aluminum cable tray, which typically has a slightly higher initial cost, over Hot-Dip galvanized steel cable tray? The answer lies in aluminum’s many advantages in design, installation, delivery, performance and total cost over the lifetime of the installation.

Design and Installation

Most people know of aluminum’s superior strength-to-weight ratio.[……]

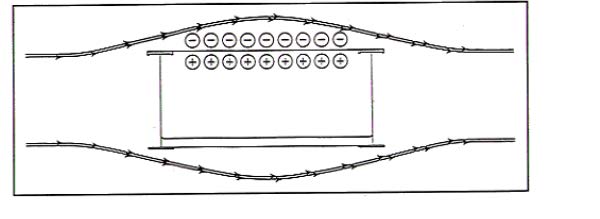

Best practice guide to cable ladder and cable tray systems (photo credit: elektro-ka.si)

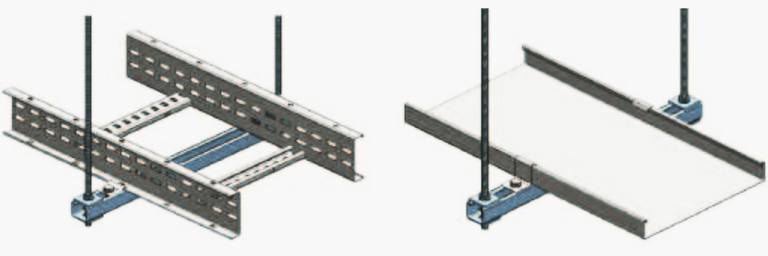

Best practice guide to cable ladder and cable tray systems (photo credit: elektro-ka.si) Channel type trapeze hangers – Installation with ladder and tray

Channel type trapeze hangers – Installation with ladder and tray [……]

[……]